Manufactured to ISO 15 (DIN 625) Standards.

GMN radials are also manufactured to ABEC 7, ABEC 9 standards with a designated precision class of 4 (P4) and 2 (P2).

GMN Radial Ball Bearing Specs at a Glance:

- Single-row bearings

- Inner diameter (mm): 5 to 40

- Outer diameter (mm): 16 to 80

- Ball Material Options: 52100 Bearing Tool Steel or Ceramic (Si3N4)

- Cage Material Options: Phenolic Resin (standard) or Polyamide with Fiberglass fill (other options available)

- Internal Clearance Options: C2, CN, C3, C4

- Shields: Open, One-sided or double-sided (lubricated)

- Heat-treated for temperatures up to 302°F (150°C)*

- Standard contact angle of 8°

- Extra-wide bearing sizes available

* Higher heat stabilization can be done upon request.

*Delivery time for this item is 1-4 weeks

Radial Ball Bearings Applications

GMN Bearing USA engineers work across markets and applications. P&P can help you find the best radial ball bearing for your unique needs and requirements. GMN radial ball bearings are used in:

- Machine-Tool Spindles

- Aircraft Generators (Hybrid)

- Biotechnology Equipment (Hybrid)

- High-Speed Mills (Hybrid)

- Precision Instruments (Hybrid)

- General Machinery (such as compressors, pumps, and electric motors)

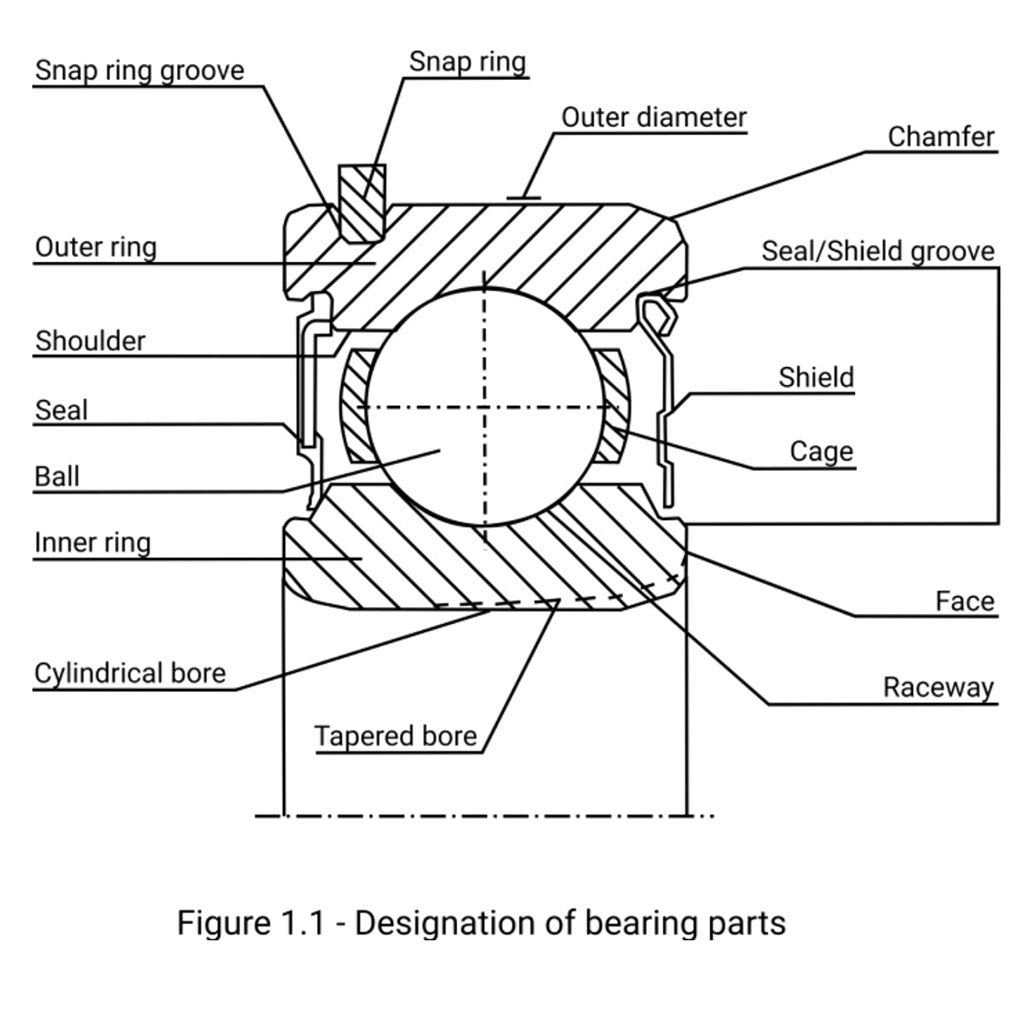

GMN 6000 & 6200 Series Radial Ball Bearings are sometimes called “deep groove” ball bearings, and they are the most popular type of high-precision bearings. These versatile bearings are great when space is a limiting factor, need low to moderate RPMs & axial loads move bidirectionally.

Top characteristics of the 6000 & 6200 Series Radial Ball Bearings:

- Single row, steel or ceramic balls

- Various cage options, including phenolic resin, polyamide w/ fiberglass & more

- Extra-wide sizes available

View GMN Radial Bearing Selection Guide (pdf)

View full selection of bearings (pdf)

Contact Us for a price quote (see contact form above ↑)